Nowadays, non woven fabrics products and bags are very popular. There is a very high demand for non woven bags. From a normal consumer to various shop owners, outlets owners, showroom owners demands for a non woven bag. This increase in demand is just to ensure that our environment is safe and it’s not getting harmed due to our day to day purchasing activities. Because many people across China always ask for a polythene bag when they have to purchase anything from any shop. There are charges applicable to take a non woven paper bag. Because it’s a little more expensive than normal polythene bags.

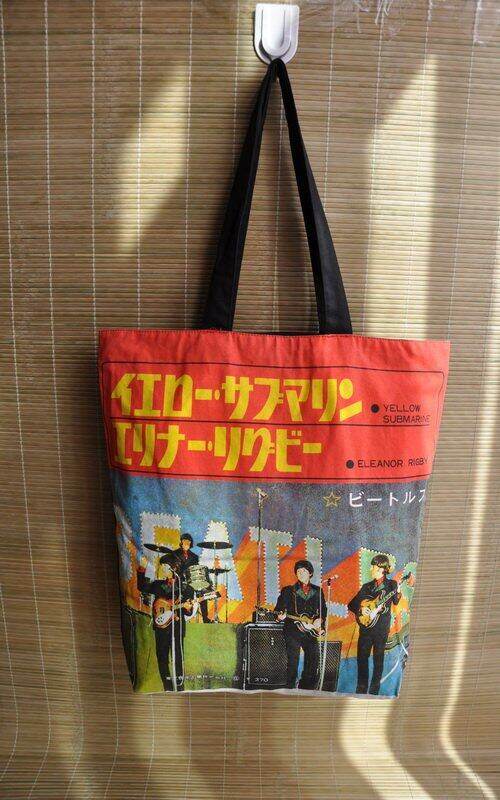

A non woven bag can be designed or customized with a non woven bag making machine. In that bag, anything can be printed ranging from the shop name to its logo and other things.

A non woven bag or paper bag is produced or manufactured with a non woven bag making machine. But there is not a single step of manufacturing it, there are various steps. Some of the steps are discussed in this blog which will let you know the production of a non-woven bag

Web formation – This first step in the manual turning process means determining the key properties of a final non-woven bag. The process of web formation from the non-woven bag making machine is based upon the textile carding process. The fibrous web needs to be formed with the non woven fabric so that to move a step forward in the manufacturing process of the non woven bag.

Web bonding – This process refers to the tieing or forming of the webs into a structure to form a non woven bag. This step can be done in a non woven bag making machine. Whereas there is no need of doing or performing this step manually. The fabrics will be knitted to the fibers to form an interlocking position of the non woven bag. In this process, a thermal bonding process is also required for heating or stabilizing the bond with a thermoplastic fiber. The fibers in the half knitted woven bag will act as the thermal binders which use latex or resins binders.

Finishing and converting – This is one of the important processes because after this process the non woven from the non woven bag making machine will directly reach the customers. Therefore giving it a finishing touch with lamination and other customization and converting it to perfection is important for a non woven bag. With this process done, a consumer can ensure getting one of the most eco-friendly bags.

These points given above will be required in the manufacture of a non woven bag. This manufacturing process will guide the consumers and shopkeepers to get the surety about the 100% pure non woven bag. Even if you are thinking of starting a business for a non woven bag making machine this will help you in establishing the best and profitable business. Start your one step ahead towards establishing a secure and safe place of living.