The biggest feature of non-woven bag is that its material is very tough. Even if we use it for a long time, we will not damage it. Not only that, the appearance of many non-woven bags on the market is very fashionable and beautiful, and the air permeability is very good. Anything in it will not lose its “life”. Such non-woven bags in the production process steps are also very complex, not only that, but also its production is classified. The production process of non-woven bags for different purposes is different.

Why should the surface be shiny when choosing a fabric? This is because the surface of the fabric is glossy. In this way, to prepare for the later printing, one is good printing, and the other is that the printed effect will be very good. In this way, the overall effect will be very prominent, and such non-woven bags will surely be deeply loved by consumers.

So, why do you want a harder fabric? This is because a harder fabric can stand up and hold up, highlighting the overall feeling of the non-woven bag, which is very practical. When shopping, put a certain weight on it. The object will not be broken or broken. Safe and practical, this is the standard for non-woven bags.

Similarly, the difference in the vertical and horizontal tension of the fabric is required to be small, which is also to ensure that the non-woven bag has an excellent performance in terms of load-bearing.

How do make these large rolls of non-woven fabrics into bags? Yes, it’s just what you think, cut it into pieces, strips of small fabrics.

According to the size, use an automatic slicer and a strip cutter to cut the fabric into small pieces of the required size. Among them, the divided large piece is a three-sided conjoined body with the front and back plus the bottom for printing. Then there is the side, carrying the hand, and wrapping the edge strips. This is the so-called cutting strip, which refers to this kind of handle and edging. Because they are very narrow, they must be cut into very small strips to match the processing of the finished product.

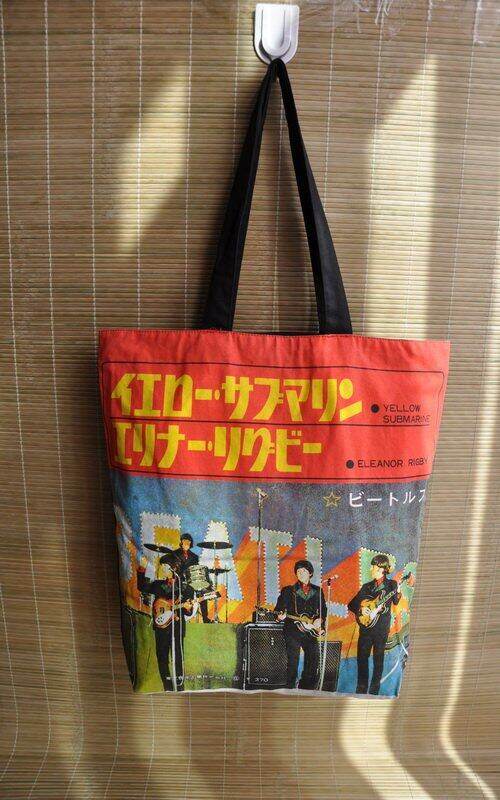

It’s printing. Screen printing is generally used. Because it is printed by hand, its speed and progress will be slower than that of machine printing. Of course, the cost will be higher than that of machine printing, but it The advantages of this are also very obvious. It can print in a small amount, and the error rate is relatively low. When printing, pay attention to the printed text, the pattern should have a good fullness, and the size should be able to highlight the effect of the entire non-woven bag.

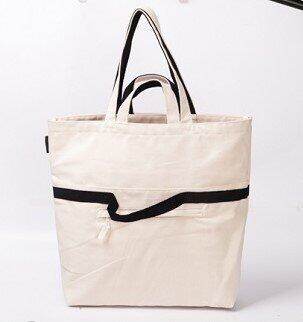

Sewing, according to certain specifications and styles, like sewing clothes, stitch together large pieces of fabric, small pieces, handles, hemming, and other fabrics to become the finished non-woven bag that you see.

There are many sewing methods in this. For example, at the interface of the handle and the large piece, there is no need to cross the cross. The cross is to increase the firmness. On the side are a few threads, the length of the strap, and so on.

The final step is to pack and box. Use cardboard boxes according to certain specifications, 100 per box, or 200 per box, with fonts printed on the boxes, so that boxes of finished non-woven bags will be transported through logistics. Each terminal is sold to a wide range of consumers.

Neway Ecobag produce and supply high quality spunbond nonwoven fabric, pp+pe,meltblown nonwoven fabric,spunlace nonwoven fabric.